You can perform maintenance on your certified aircraft, legally,

if you know these important details.

As aircraft owners there is a lot to think about. Insurance, storage, fuel, fees, and all these items can be costly, but there are ways to save money.

One of the largest costs we face is maintenance. As an Aircraft Maintenance Engineer (AME), I know the work that is necessary to maintain an aircraft. I also know that regular care and attention to the maintenance needs of your aircraft will save time and money in the long term.

While this is easy to say this from an AME standpoint it is another to say it from the point of an aircraft owner.

I have owned several different aircraft over the last 16 years, I know the struggles and costs of owning and operating an aircraft. I also know owners who experience a lot of frustration over the inability to perform their own maintenance. This is why a trusting relationship between an owner and AME is crucial.

There are commonly known ways to help keep your maintenance costs under control. Flying regularly is the best option. Your aircraft performs best when it receives regular exercise. Staying on top of issues and scheduled maintenance also helps immensely. The whole “pay now or pay later” scenario.

For owners who do not also have an AME licence, not being able to touch their aircraft is frustrating, but, there are in fact several maintenance tasks you can legally perform on your certified aircraft.

The Canadian Aviation Regulations is a labyrinth of information but buried in CAR 625 Appendix A is a list containing 29 items. Many of these items are common maintenance tasks performed on general aviation aircraft. Owners can perform these 29 items on their own, without the requirement to hold an AME licence.

There are two important aspects of Elementary maintenance that need to be discussed. First, CARs states, “The following list is exhaustive; if a task is not listed, it is not elementary work.” This means the list they give is the list you have.

Attempting work outside of this list, without being the holder of an AME licence, is illegal. So please don’t try to invent grey areas or bend the rules. You are better off finding a good AME you can work with to help you with your other maintenance needs.

Next, it states “The performance of all tasks designated as elementary work shall be entered in the technical record for the aeronautical product, as required by section 571.03 of the CARs and in accordance with Subpart 605, Division IV – Technical Records.”

This means any work you do, must be properly recorded. If you have never used technical records before, they are easy but must contain important information regarding your work. Again, speak to a trusted AME to ensure you are properly documenting all the necessary details of your work.

Training

As with all aspects of aviation, there is training required before you can perform these tasks. CAR 604.128 lists the required training for elementary maintenance. The biggest point being "in the case of elementary work, has performed that work at least once under the supervision of the holder of an aircraft maintenance engineer (AME) licence or the holder of an approved training organization certificate".

In short, any of these task must be carried out with the proper manufacturer data, tooling and procedure as if you were an AME yourself. Just like straying from the list itself, not following proper procedure can cause airworthiness and liability issues, so be sure to research and ask for guidance when needed.

If done properly, performing these tasks will not only help you save money on your maintenance costs, but they will also teach you a lot about your aircraft and what makes it tick. Below is the complete list of tasks, take a look, and see if there are any items you feel you can tackle.

Finally, don’t be scared to ask for help. Your AME and aviation community are here to help.

Elementary Work Task Listings

(1) fabric patches measuring not more than 15 cm (6 in) in any direction and not requiring rib stitching or the removal of control surfaces or structural parts, on small privately operated aircraft;

(2) removal and replacement of tires, wheels, landing skids or skid shoes, not requiring separation of any hydraulic lines, on small privately operated aircraft;

(3) removal and replacement of skis on fixed landing gear, not requiring separation of any hydraulic lines, on small privately operated aircraft;

(4) repair of non-structural fairings, cover plates and cowlings, on small privately operated aircraft;

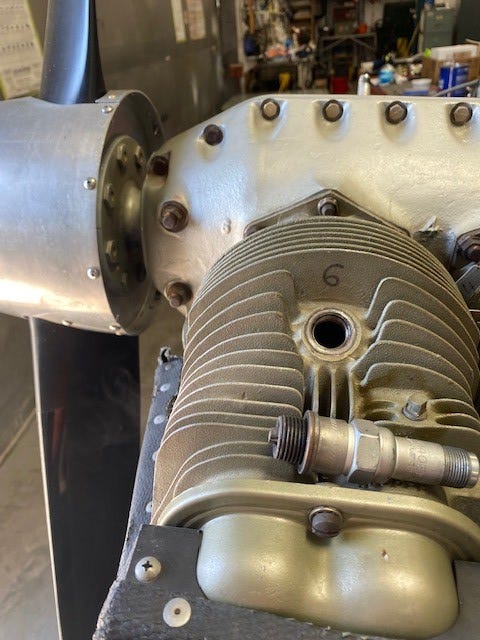

(5) cleaning and replacement of spark plugs, on small privately operated aircraft;

(6) checking of cylinder compression, on small privately operated aircraft;

(7) cleaning or changing of fuel, oil, and air filters, on small privately operated aircraft;

(8) draining and replenishing engine oil, on small privately operated aircraft;

(9) checking the electrolyte level and specific gravity of lead acid batteries, on small privately operated aircraft;

(10) adjustment of generator or alternator drive belt tension, on small privately operated aircraft;

(11) cleaning of balloon burner nozzles;

(12) removal and replacement of balloon baskets, burners and gas tanks that are designed for rapid change in service;

(13) removal and replacement of glider wings and tail surfaces that are designed for quick assembly;

(14) repair of upholstery, trim and cabin furnishings;

(15) removal and replacement of role equipment designed for rapid removal and replacement;

(16) removal and replacement of passenger seat belts and harnesses;

(17) removal and replacement of fuses, light bulbs and reflectors;

(18) removal and replacement of avionics components that are rack mounted or otherwise designed for rapid removal and replacement, where the work does not require testing other than an operational check;

(19) removal and replacement of aircraft batteries;

(20) removal and replacement of co-pilot control levers, wheels, pedals and pedal guard plates that are designed for rapid removal and replacement, on other than transport category aircraft;

(21) opening and closing of non-structural access panels;

(22) removal and replacement of cabin doors on unpressurized aircraft, where the door is designed for rapid removal and replacement;

(23) removal, replacement and repositioning of non structural partitions in the passenger cabin;

(24) inspection and continuity checking of self-sealing chip detectors;

(25) removal and replacement of induction system anti-icing baffles, scoops and deflectors that are designed for rapid removal and replacement;

(26) removal, cleaning, replacement and adjustment of external components of chemical dispersal systems that are designed for rapid removal and replacement;

(27) deactivating or securing inoperative systems in accordance with sections 605.09 or 605.10 of the CARs, including the installation of devices specifically intended for system deactivation, where the work does not involve disassembly, the installation of parts, or testing other than operational checks;

(28) checking and adjusting air pressure in helicopter floats and aircraft tires except on aircraft operated under CAR 705.

(29) repetitive visual inspections or operational checks (including inspections and tests required by airworthiness directives) not involving disassembly or the use of visual aids, performed out of phase with the aircraft’s scheduled check cycle at intervals of less than 100 hours air time, provided the tasks are also included in the most frequent scheduled maintenance check.